QUALITY CONTROL

In terms of quality management, we have set inspection standards for each stage of the production process. During production, we use custom-made specific gauges for inspection to quickly screen out qualified products. We also conduct regular inspections daily to monitor various processing conditions, thus providing timely supervision and stringent quality control for your products.

In terms of quality management, we have set inspection standards for each stage of the production process. During production, we use custom-made specific gauges for inspection to quickly screen out qualified products. We also conduct regular inspections daily to monitor various processing conditions, thus providing timely supervision and stringent quality control for your products.

We have experienced professionals and various professional measuring tools to ensure the integrity of the products. From surface penetrant testing to imported German metal X-RAY computer tomography, we conduct comprehensive 2D or 3D inspections to detect internal flaws in the metal. For contour dimensions, we use Japanese projection image measuring instruments and 2.5D image measuring instruments, effectively and quickly measuring a variety of specification requirements. For precise machining dimensions, we use precise gauges to carry out detailed inspections one by one on a granite measurement table.

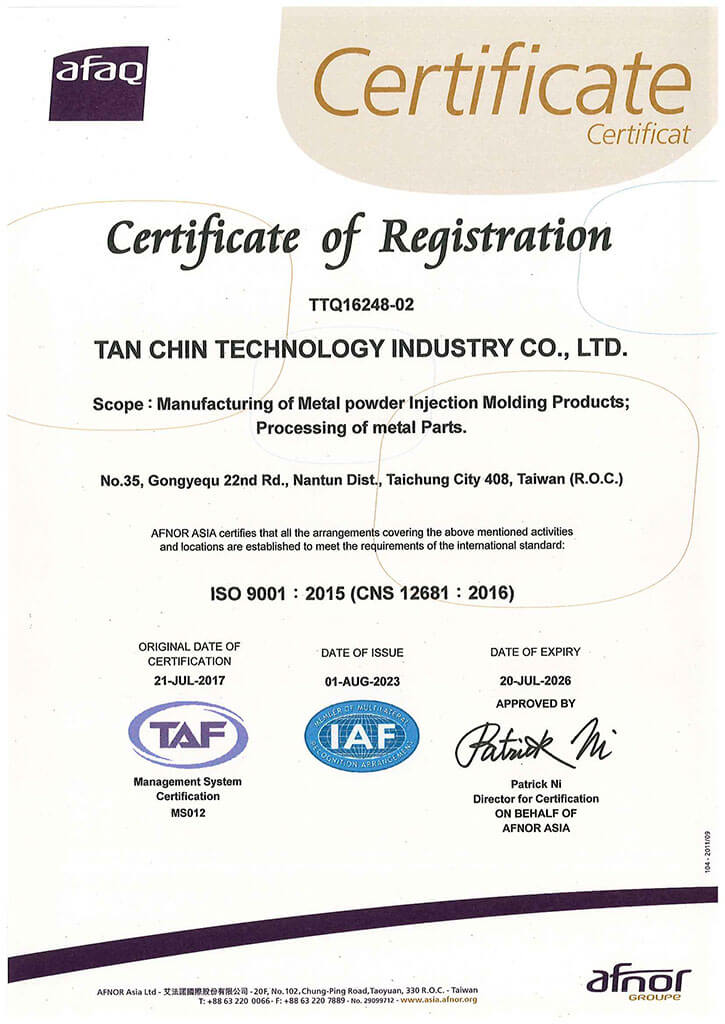

Complying with the various requirements of ISO 9001:2015 forms the basis of our quality assurance. We tirelessly maintain the operation of each procedure and continue to accept the challenge of verification every year!

Our commitment to quality improvement is unending; we aim to provide the best service and achieve customer satisfaction.