Process Capability

We have chosen Japanese FANUC 50 & 100-ton injection molding machines, combined with various special injection molding molds we developed. We use X-RAY to improve internal and external defects, greatly enhancing production efficiency and stable quality. Our sintering furnaces are from Japan's Shimadzu and American vacuum sintering furnaces. After continuous testing and condition improvements, we have developed a shorter sintering time with stable quality. We continuously improve and research various MIM production conditions to enhance our technology and capabilities.

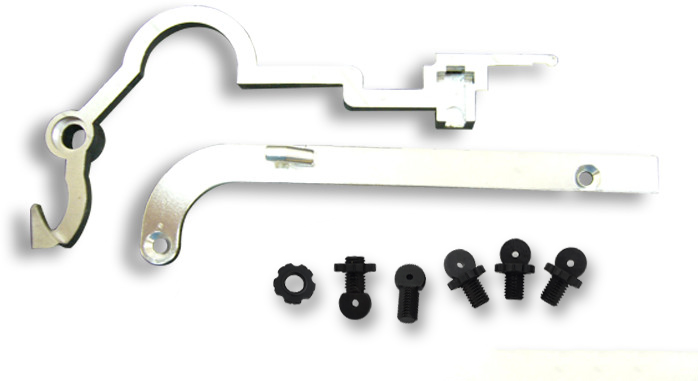

We have many different types of machine tools, including drilling machines, milling machines, lathes, grinding machines, punch presses, and various kinds of modified processing equipment. Therefore, after the MIM raw material is formed and sintered, we can control the stable dimensions according to your product requirements. Whether it's shaping, drilling, reaming, tapping, grinding, or turning, we can further perform precision processing.

MIM manufactured parts can be widely used in various industries, such as sewing machines, toy guns, medical, diving, electronics, automobiles, bicycles, mechanical hardware parts, etc. The selection of materials includes iron-nickel alloys, chrome-molybdenum alloy steel, stainless steel, tungsten carbon steel, high-speed steel, which can be chosen according to product characteristics.

We have professional MIM manufacturing technology and many years of processing experience since our establishment. For any production and manufacturing problems, we have many experienced engineering technicians, coupled with professional knowledge and skilled techniques, to jointly discuss and formulate the most suitable production conditions, the most stable engineering sequence, and special production molds. Therefore, we can solve even the most difficult problems.