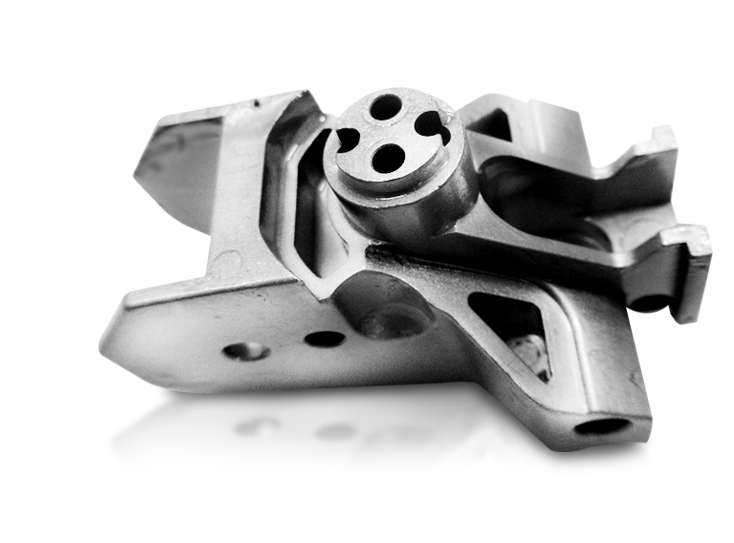

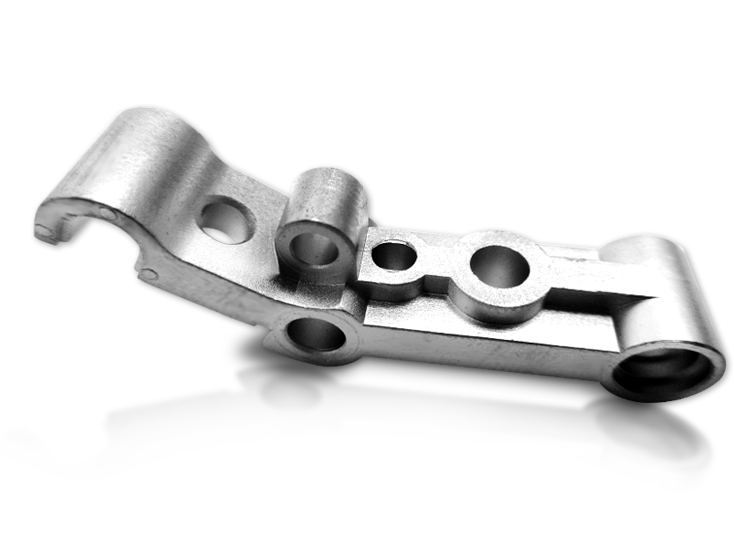

MIMExpansion Journey

- 1996: Introduced and continuously researched MIM technology.

- 1997: Equipped with an American vacuum furnace and two injection molding machines.

- 2002: Equipped with various injection molding and mixing machines.

- 2004: Added a second Japanese vacuum sintering furnace and two injection molding machines.

- 2005: Continuously added equipment and a third vacuum sintering furnace.

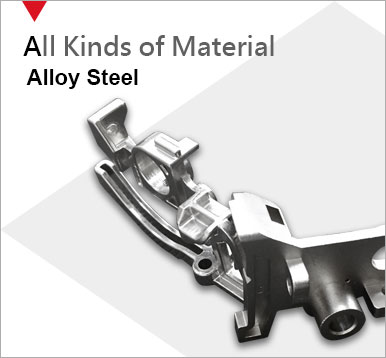

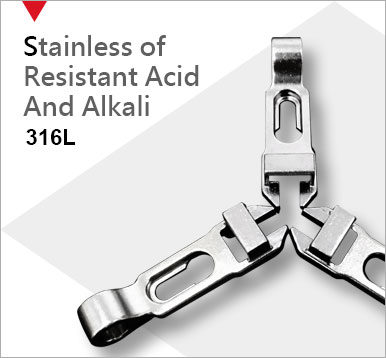

- 2008: Developed a variety of materials for use in MIM.

- 2013: Developed over 800 customized MIM parts.

- 2016: Added a fourth vacuum sintering furnace and magnetic powder flaw detection equipment.

- 2017: Passed ISO9001:2015 Quality Management System.

- 2018: Invested hundreds of millions to expand land scale and business development.

- 2022: Added 4 more Japanese sintering furnaces and injection molding machines.

- 2023: Purchased German metal X-RAY computer tomography equipment.

Continuously striving to research MIM technology and expand the industry scale.

886-4-23591191

886-4-23593343