ABOUT US

Excellently manufacturing products is our quality commitment to you, Promptly meeting what you want is our heartfelt service to you.

Our company was established in 1980, starting with the production of sewing machine parts such as shuttle hooks and bobbin cases. We cooperated with Brother Industries in Japan to develop and produce high-quality parts specifically for aluminum alloy sewing machines. The quality of our products has been highly recognized by our customers.

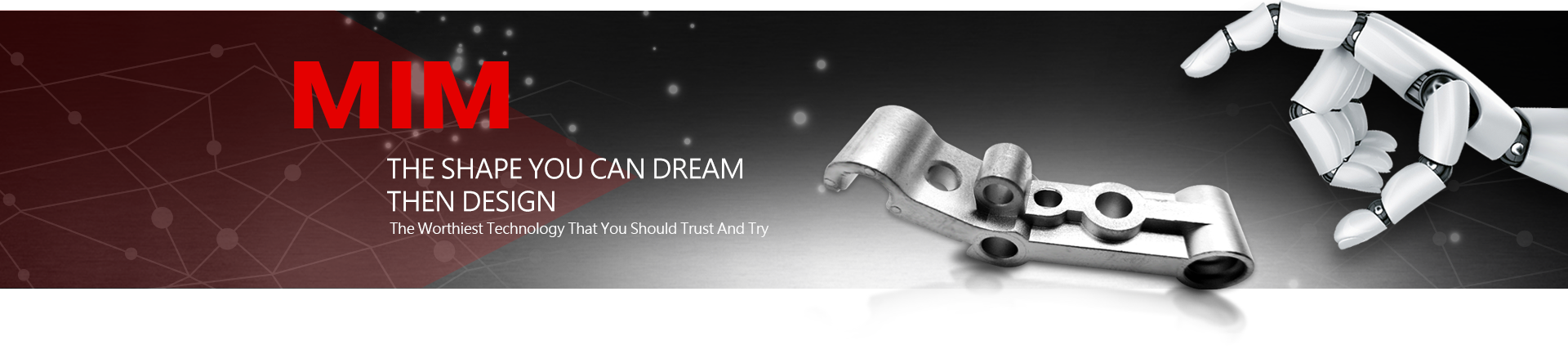

In 1997, we officially introduced MIM technology and equipment, replacing the process of purchasing raw materials for further processing. Since our establishment, we have always valued the management of production, quality, and equipment. We actively discuss the latest MIM technologies and continuously improve our processing techniques. Guided by our principles of quality first and customer priority, we continue to plan for the next phase of expansion.

From 1998 to 2006, our MIM technology was among the leaders in Taiwan, and we began to accept customer requests to develop MIM parts. During this period, we continually added sintering furnaces, injection machines, and various material mixing equipment, becoming a major MIM manufacturing factory in Taiwan.

By 2015, we had developed over 1000 different parts, with projects covering embroidery machines, 3C product parts, mechanical parts, hand tool parts, and gaming firearm parts, among others. MIM is suitable for producing precise and complexly shaped metal parts, making it applicable to a variety of industries. Currently, we have expanded into medical equipment, leisure equipment, industrial precision structural parts, and so forth. Our trading scope has gradually expanded from Taiwanese manufacturers to overseas professional manufacturers in Europe, America, and Japan. We also exchange information and discuss technology with entities all around the world, striving for continuous progress together.

In 2017, our company officially obtained ISO 9001:2015 certification. By 2023, we expanded our factory area to over a thousand pings and invested tens of millions in various equipment, making us an internationally certified MIM professional manufacturing factory. However, the demand for precise and small metal parts in the future market will continue to rise. In response to market changes and industry growth considerations, we continue to improve production techniques and management systems, introduce various equipment, and enhance process capabilities. We remain committed to excellent quality and timely delivery, making comprehensive preparations for the future. Above all, we strive to provide our customers with satisfactory service and uphold our promise of top-notch quality!

MIM technology was announced by ParmaTech, a company in California, USA.

Our company was established as a manufacturer of sewing machine shuttles and shuttle boxes.

Introduced and continuously researched MIM (Metal Injection Molding) technology.

Started to accept customer orders for the development of MIM parts.

Officially transformed into a major MIM manufacturer in Taiwan, with a production capacity of 3 tons per month.

The factory equipment reached six injection molding machines and three vacuum sintering furnaces.

Developed more types of MIM metal materials, with a production capacity of 8 tons per month.

Hired professional management personnel and heavily computerized equipment management.

The company developed over 1000 custom parts.

Added vacuum sintering furnace, magnetic particle inspection equipment, and liquid dewaxing system.

Passed ISO 9001:2015 quality management system certification.

Invested heavily to expand the land scale to a thousand pings in preparation for the future.

Renovated the newly purchased factory, and purchased four more Japanese sintering furnaces to increase production capacity.

Added four new injection molding machines, significantly increasing monthly production capacity.

Added German metal X-RAY 3D computer tomography equipment to enhance process capabilities and quality.

Continues to plan for business expansion and anticipate future trends.